Enhancing Rice Processing Efficiency with Paddy Cleaners: Everything You Need to Know

In the rice milling industry, efficiency and quality go hand in hand. One of the most essential machines in this process is the Paddy Cleaner. This equipment plays a vital role in the initial stage of rice processing by removing unwanted materials from paddy, ensuring only clean grains proceed to the next steps.

For rice millers looking to enhance productivity, reduce waste, and maintain grain quality, understanding the function and benefits of paddy cleaners is crucial. In this blog post, we’ll explore the importance of paddy cleaners, how they work, types available in the market, and how Ricetec Machinery stands out in providing advanced cleaning solutions for modern rice mills.

What is a Paddy Cleaner?

A Paddy Cleaner is a pre-cleaning machine used to remove impurities from raw paddy before it enters the rice milling process. These impurities may include:

-

Dust

-

Straw

-

Stones

-

Chaff

-

Weed seeds

-

Other foreign particles

By removing these contaminants early, the paddy cleaner helps improve the efficiency of subsequent milling stages and protects downstream equipment from damage.

Importance of Paddy Cleaning in Rice Milling

The rice milling process begins with raw paddy which often contains various impurities picked up during harvesting, transportation, and storage. Neglecting the cleaning stage can lead to:

-

Lower milling efficiency

-

Increased wear and tear on machinery

-

Poor-quality rice output

-

Higher maintenance costs

Cleaning paddy before milling not only ensures better quality output but also helps extend the life of milling machinery. This is why the paddy cleaner is often considered the foundation of a well-functioning rice mill.

How Does a Paddy Cleaner Work?

The working principle of a paddy cleaner involves the mechanical separation of impurities based on size, weight, and aerodynamic properties. Here’s a general overview of how it operates:

-

Feeding Section: Raw paddy is fed into the machine via a hopper.

-

Aspiration System: Lightweight impurities like dust, husk, and straw are removed by an air blower or suction fan.

-

Sieving Mechanism: The remaining paddy passes through a series of vibrating or rotating sieves that separate out larger and smaller impurities.

-

Outlet Section: Clean paddy is discharged for further processing, while impurities are expelled through separate outlets.

This combination of air and mechanical separation ensures thorough cleaning of the paddy.

Types of Paddy Cleaners

There are different types of paddy cleaners available, each suited to specific milling requirements and capacities. The main types include:

1. Vibratory Paddy Cleaner

This is the most common type and uses vibrating screens to separate impurities. It is highly efficient and suitable for small to medium-capacity rice mills.

2. Rotary Paddy Cleaner

Rotary cleaners use a rotating cylindrical sieve to separate particles. They are durable and effective for larger volumes of paddy.

3. Aspirator Cleaner

Primarily used to remove lightweight particles using airflow. Often used in combination with vibratory or rotary systems for more comprehensive cleaning.

4. Pre-Cleaner with Magnetic Separator

This advanced version includes magnetic components that remove metallic impurities, providing additional protection for downstream equipment.

Key Features to Look for in a Paddy Cleaner

When selecting a paddy cleaner for your rice mill, consider the following features:

-

High Cleaning Efficiency: Ability to remove a wide range of impurities effectively.

-

Adjustable Sieves: Flexibility to handle different grain sizes.

-

Low Power Consumption: Energy-efficient operations to reduce costs.

-

Durable Build: Long-lasting components that withstand heavy-duty usage.

-

Minimal Maintenance: Easy access for cleaning and part replacement.

-

Customizable Design: Suitable for integration into different plant layouts.

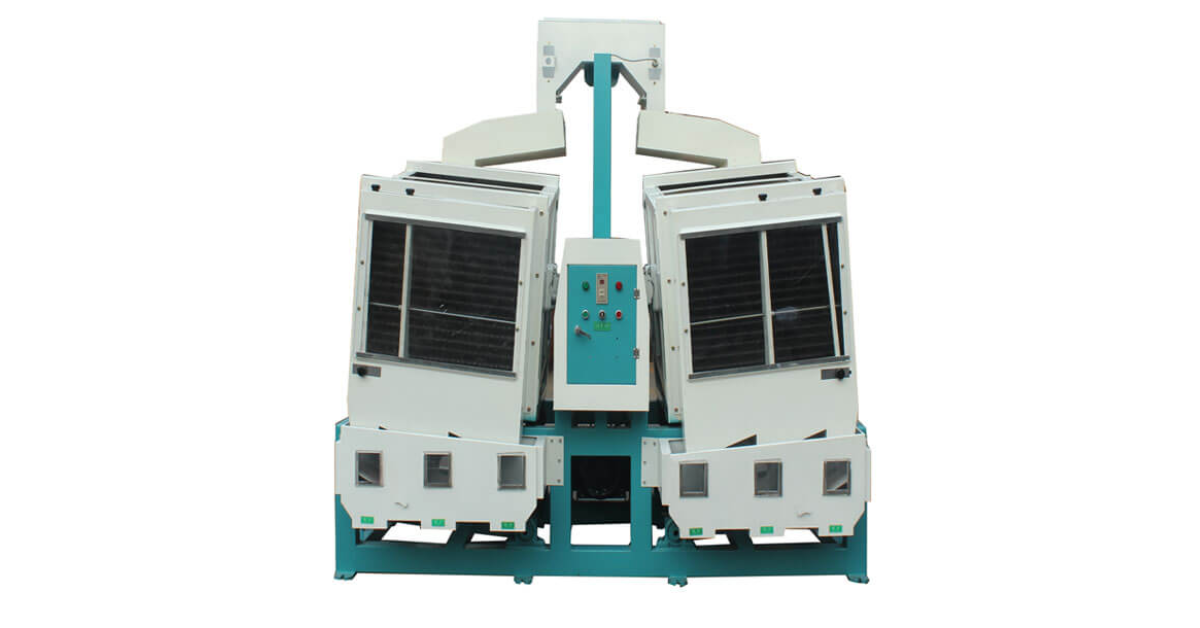

Ricetec Machinery: Delivering High-Performance Paddy Cleaners

Ricetec Machinery is a trusted name in the rice milling industry, known for its commitment to innovation, quality, and customer satisfaction. The company offers a wide range of Paddy Cleaners tailored to meet the needs of both small-scale and large-scale rice mills.

Why Choose Ricetec Paddy Cleaners?

-

Proven Performance: Designed to deliver consistent results in diverse operating conditions.

-

Advanced Technology: Equipped with modern features for enhanced automation and efficiency.

-

Robust Construction: Built with high-quality materials to ensure durability and longevity.

-

Customer-Centric Design: Custom solutions that match individual client requirements.

-

Excellent After-Sales Support: Technical assistance and maintenance services to keep operations running smoothly.

With a focus on innovation and customer success, Ricetec Machinery helps rice millers optimize their production while ensuring superior grain quality.

Benefits of Using a Paddy Cleaner in Rice Mills

Here are the main benefits of incorporating a high-quality paddy cleaner in your rice processing line:

1. Improved Grain Quality

By removing all contaminants before milling, the resulting rice is of higher quality with better appearance and shelf life.

2. Reduced Equipment Damage

Clean paddy reduces the likelihood of foreign objects damaging downstream machines such as dehuskers and polishers.

3. Higher Milling Yield

With fewer impurities, the milling process becomes more efficient, leading to higher recovery of whole rice grains.

4. Lower Operating Costs

Less downtime and fewer repairs mean reduced operating and maintenance costs in the long run.

5. Compliance with Standards

Clean paddy meets food safety and export standards, which is essential for millers targeting global markets.

Maintenance Tips for Paddy Cleaners

To ensure consistent performance and a longer service life, follow these maintenance tips:

-

Regular Cleaning: Clear out dust and debris from sieves and fans daily.

-

Lubricate Moving Parts: Follow the manufacturer’s schedule for lubrication to avoid wear and tear.

-

Check for Wear: Inspect screens and belts for damage or blockages.

-

Replace Worn Parts: Use genuine spare parts for replacements to maintain machine integrity.

-

Professional Servicing: Schedule periodic maintenance checks by trained technicians.

Future of Paddy Cleaning: Trends to Watch

The rice milling industry is evolving with advances in automation, AI, and smart controls. Paddy cleaners are becoming more intelligent, featuring:

-

Sensor-Based Monitoring: Real-time feedback on machine performance.

-

Remote Operation: Control and diagnostics via mobile or web interfaces.

-

Energy Optimization: Smart algorithms to reduce power usage.

-

Modular Design: Easy upgrades and scalability for growing mills.

Investing in modern paddy cleaning technology positions millers to stay competitive in a fast-changing market.

Frequently Asked Questions (FAQ)

What is the role of a paddy cleaner in rice milling?

A paddy cleaner removes impurities such as dust, stones, straw, and chaff from raw paddy before it enters the milling process. This ensures better quality output and protects milling equipment from damage.

How do I choose the right paddy cleaner for my rice mill?

Factors to consider include the scale of your operation, type of paddy, desired cleaning efficiency, and available space. Consulting with a supplier like Ricetec Machinery can help you select the most suitable model.

Is a paddy cleaner necessary for small-scale rice mills?

Yes. Even small-scale mills benefit from using a paddy cleaner, as it improves output quality, reduces equipment wear, and increases overall productivity.

How often should a paddy cleaner be maintained?

Basic cleaning should be done daily, while detailed maintenance should follow the manufacturer’s schedule. Periodic inspections can prevent costly breakdowns.

Can a paddy cleaner remove all types of impurities?

High-quality paddy cleaners can remove most common impurities. For specialized contaminants like metals, additional equipment like magnetic separators may be required.

Conclusion

A Paddy Cleaner is a crucial investment for any rice mill aiming to boost productivity and quality. From safeguarding expensive equipment to ensuring superior rice output, the benefits of this machine are far-reaching. At Ricetec Machinery, we understand the dynamic needs of the rice processing industry and provide tailored solutions that deliver both performance and reliability.

Whether you are upgrading an existing mill or setting up a new facility, Ricetec’s paddy cleaning solutions are engineered to give you the best possible start in your rice milling journey.